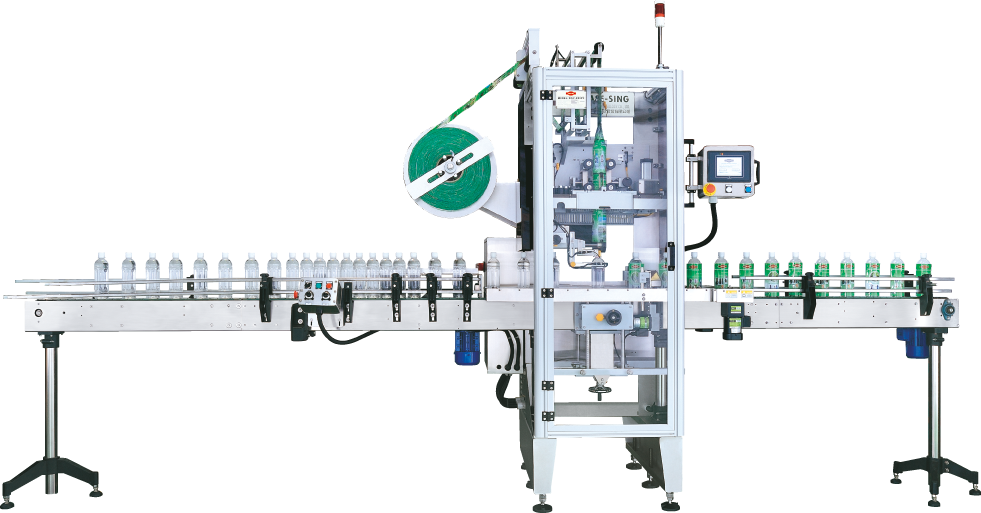

Single-head DSV-200P2 (up to 200BPM)

Specification

Low speed

Sleeve gauge >30 micron

Standard change over

| Max speed | 200BPM |

|---|---|

| Bottle Diameters | Ø25mm~Ø125mm (Based on the bottle dimension of specification provided by the customer) |

| Film Material | PVC /PET /OPS |

| Film Width | PVC:0.035mm~0.08mm, PET:0.04mm~0.06mm,OPS:0.04mm~0.06mm |

| Machine Size | 1403mm*960mm*2090mm(L*W*H) (Dase-Sing reserves the right to mofify the apperarance and dimension of the machine, in order to optimize the fuction of the requirement) |

| Voltage | 220V (According to customer requirement) |

Based on research improvement necessity, DASE-SING reserves the right to revise the machine design and specification without any notice.

Machine Features

- Can be fully integrated within production line.

- Safety guards and color touch panel control system ensure unit is user friendly.

- Specially designed cutter plate does not need changing within rated specifications. If necessary, changes can be accomplished in only three minutes.

- Integrated adjustment design of the entire transmission maximizes versatility for accommodating different label specifications.

- Accommodates film paper core sizes of 5 to 10 with variable adjustments.

- PLC (Programmable Logic Control) for increased accuracy and speed over conventional controls.

Innovative Features

- Compact design for convenient installation and reduced floor space.

- Easy to increase production capacity with additional main units. No need to install the feeding screw for a second unit. This allows shorter conveyor lengths to help optimize usage of floor space.

- Capping and labeling units can be put together in the same production line. Production capacity increases when body sleeving is applied to both machines Also suitable for simultaneous production of bottles with different sleeve packaging requirements. Save time and labor, and increase efficiency.

- Perforation device for tamper evident caps available.