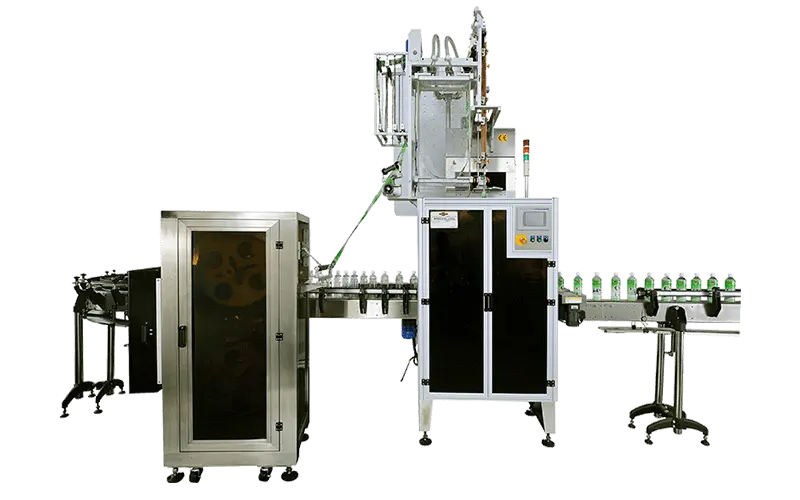

Single-head DSL-600A (up to 600BPM)

The DSL‑600A is a high‑speed, single‑head shrink sleeve applicator capable of up to 600 bottles per minute. Built with precise servo control, a robust structure, and Allen Bradley PLC integration, it ensures consistent labeling across a wide range of bottle sizes (Ø25–125mm).

Featuring quick sleeve changeover, operator‑friendly touch panel controls, and multi‑protocol connectivity (EtherNet/IP, Profibus, DeviceNet), the DSL‑600A helps manufacturers boost efficiency while reducing downtime. Optional accessories, such as a ground label unwinder or perforation device, further enhance flexibility for specialized applications.

Specification

High speed

Sleeve gauge >20 micron

Quick change over

| Max speed | 600BPM |

|---|---|

| Bottle Diameters | Ø25mm~Ø125mm (Based on the bottle dimension of specification provided by the customer) |

| Film Material | PVC /PET /OPS |

| Film Width | PVC:0.035mm~0.08mm, PET:0.04mm~0.06mm,OPS:0.04mm~0.06mm |

| Machine Size | 1190mm*1090mm*3390mm(L*W*H) (Dase-Sing reserves the right to mofify the apperarance and dimension of the machine, in order to optimize the fuction of the requirement) |

| Voltage | 3P;220V,380V,415V,440V (According to customer requirement) |

Machine Features

- Multiple communications interfaces for DeviceNet, ControlNET, EtherNet/IP, Profibus DP and analog for increase system compatibility.

- Optional ground label unwinder is available for DSL-600A for convenient changing of sleeves.

- Safety guard combined with color touch panel control system ensures machine is operator friendly.

- No need to change the specially designed cutter plate within the rated specifications. Change of cutter plate in only three minutes.

- Forceful insertion designs can lower production costs.

- Integrated design for the entire transmission accommodates different label specifications of maximum convenience.

- Machine can be tilted to facilitate label insertion on straight bottles without mouth.

- With latest communication control system to increase sleeving accuracy and speed.

- Programmable servo soft motion control enhances working life and stability.

- No need to adjust label or bottle sensors when changing speeds.

Innovative Features

- Touch screen made by Allen Bradley, recognized worldwide for high quality products .

- Standard PackML Package Machine Language simplifies customization and integration.

- Automatic zero calibration.

- User friendly design-auto mode, manual mode, design parameter and I/O status.

- Quick troubleshooting search/repair process.

- Full control of the automation system thru the HMI.

- Modularized programming makes system easy to modify and maintain.

- S-Curve control of line speed acceleration/deceleration eliminates need for multi stage speeds; operators key-in target speed and the system calculates accel/decel rates automatically.

- No need to adjust mark and bottle sensors when changing speeds.

- Machine starts and stops, depending on infeed and outfeed status.

- Servo-powered index cutter synchronized with main conveyor for improved accuracy.

- Automatic synchronization with marker feature moves film to the marker for cutting, improving operator safety.

- Advanced algorithms smooth servo motor operation, reduces mechanical jerk.

- Multiple communications interfaces for DeviceNet, ControlNET, EtherNet/IP, Profibus DP and analog, to increase system compatibility.