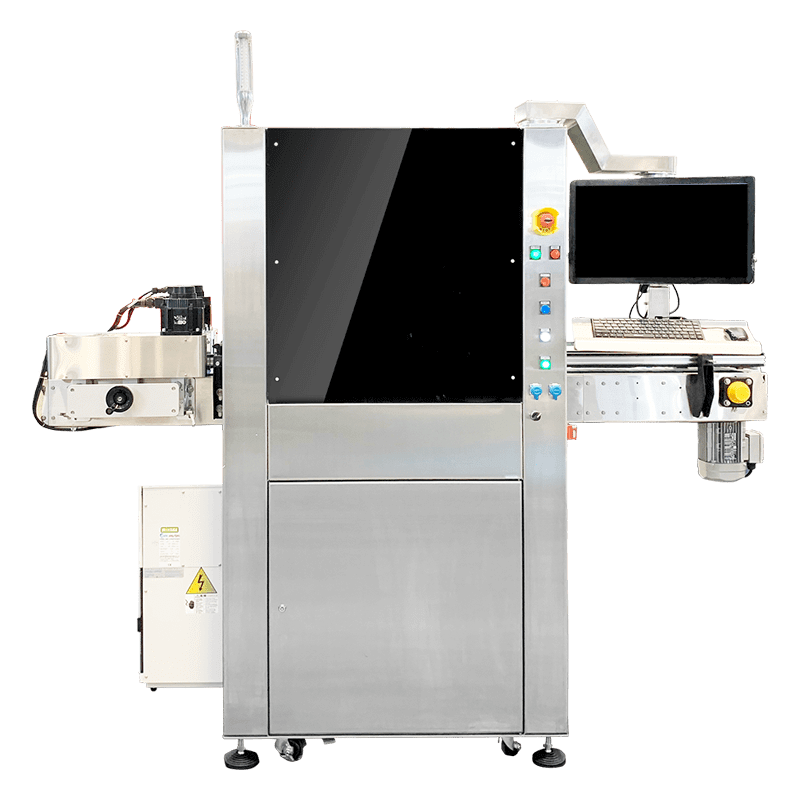

Bottle orientation machine

Dase-Sing’s Bottle Orientation Machine, also known as a Container Orientation Machine (i-Vision), plays a critical role in automating the alignment of bottles as they move along the production line. Built to handle a wide range of bottle shapes and sizes, this bottle orientation system rotates containers to a consistent orientation, ensuring downstream processes like labeling or sealing are perfectly aligned. With support for both pre-fill operations, it offers flexibility across multiple packaging setups.

Specifications

High speed

Need Spec consulting

Sleeve applicator cooperating

Model | i-Vision |

Power Supply | 3-phase, 380V / 220V |

Machine Dimensions | 1258 mm (L) × 1060 mm (W) × 2439 mm (H) (Note: To support ongoing product improvements, Dase Sing may revise machine designs and specifications without prior notice.) |

Power Consumption | 5 kW |

Production Speed | Up to 600 bottles per minute (for caps 40 mm or smaller) |

Applicable Bottle Diameter | 25 mm – 40 mm |

Compatible Label Materials | PVC, PET, OPS |

Bottle Types | Customized based on client-provided samples. Product evaluation required prior to production setup. |

Based on research improvement necessity, DASE-SING reserves the right to revise the machine design and specification without any notice.

Description

From precise bottle rotation to seamless line integration, our bottle orientation machine is built for fast-paced production environments. Below are the key features that make this container orientation machine a smart addition to any packaging line.

Key Features

Material Compatibility

Works with containers labeled using PVC, PET, or OPS shrink sleeves.

- High Speed, Non-Stop Operation

Bottles are reoriented without pausing or interrupting flow, enabling speeds up to 600 bpm (for ≤40mm caps).

Custom-Fit for Irregular Bottles

Handles a wide range of bottle shapes—especially irregular or non-symmetrical designs—based on customer samples and evaluation.

Flexible Integration

Can be installed as a standalone unit or integrated seamlessly into your existing production line.

Pre- or Post-Fill Compatibility

Offers the flexibility to be positioned before or after the filling stage, depending on packaging requirements.

Compact, Lightweight Design

Engineered for a small footprint and easy relocation within your facility.

Quick Adjustment & Maintenance

Simplified mechanisms allow for fast setup changes and routine maintenance with minimal downtime.

Optional Bottle Separator

An optional bottle-separating screw is available to ensure consistent spacing and feeding.

Dase-Sing’s Bottle Orientation System ensures your containers are aligned perfectly, every time. Contact us to discuss customization options or request a quote.