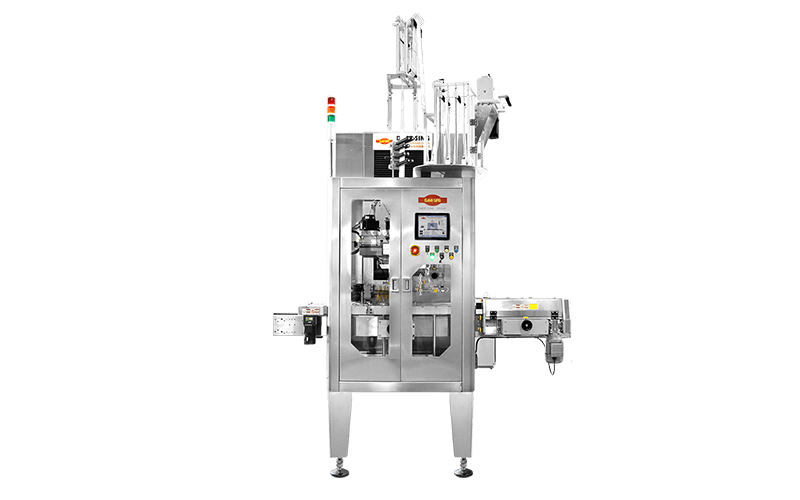

| Max speed | 500BPM |

|---|---|

| Bottle Diameters | ψ25mm~ψ125mm (Based on the bottle dimension of specification provided by the customer) |

| Film Material | PVC /PET /OPS |

| Film Width | PVC:0.035mm~0.08mm, PET:0.04mm~0.06mm,OPS:0.04mm~0.06mm |

| Machine Size | 1090mm*1130 mm*3064mm(L*W*H) (Dase-Sing reserves the right to mofify the apperarance and dimension of the machine, in order to optimize the fuction of the requirement) |

| Voltage | 3Φ220V,3Φ380V,3Φ415V,3Φ440V,3Φ480V (According to customer requirement) |

Need Some Help?

Maintenance / Inquiry / Service