.jpg)

Dase-Sing proudly showcased its latest sleeve labeling innovations at Drinktec Germany, reinforcing its reputation as a one-stop packaging solution provider. A key highlight was the unveiling of the i-Sleeve Pro II sleeve applicator, engineered for high-speed performance up to 1000BPM. The event also marked a major milestone as Dase-Sing prepared to ship advanced applicator to the EU for TÜV certification, underscoring its commitment to global quality standards and regulatory excellence.

At the show, Dase-Sing unveiled the i-Sleeve Pro II, a cutting-edge sleeve applicator capable of speeds up to 1000 bottles per minute (BPM). Engineered for precision and efficiency, this applicator is designed to meet the demands of high-volume production lines across beverage, pharmaceutical, and personal care industries.

Innovation: Downgauging Sleeve Integration

One of the key highlights was Dase-Sing’s breakthrough in downgauging sleeve technology, showcasing sleeves as thin as 20μm. This innovation not only reduces material usage and environmental impact but also maintains shrink performance and visual integrity.

Dase-Sing demonstrated how these ultra-thin sleeves are seamlessly integrated into its applicator systems, supported by specialized modules that ensure smooth feeding, accurate placement, and balanced shrinkage—even at high speeds.

As a total solution provider, Dase-Sing presented its full suite of sleeve labeling capabilities:

Sleeve material selection tailored to container shape and shrink profile

Digital and flexographic printing for vibrant, distortion-free graphics and rapid prototyping

High-speed applicators with modular enhancements

Custom shrink ovens and add-ons for precise shrink control

This integrated approach ensures consistent results across HDPE, PET, and glass containers, supporting both small-batch prototyping and full-scale production.

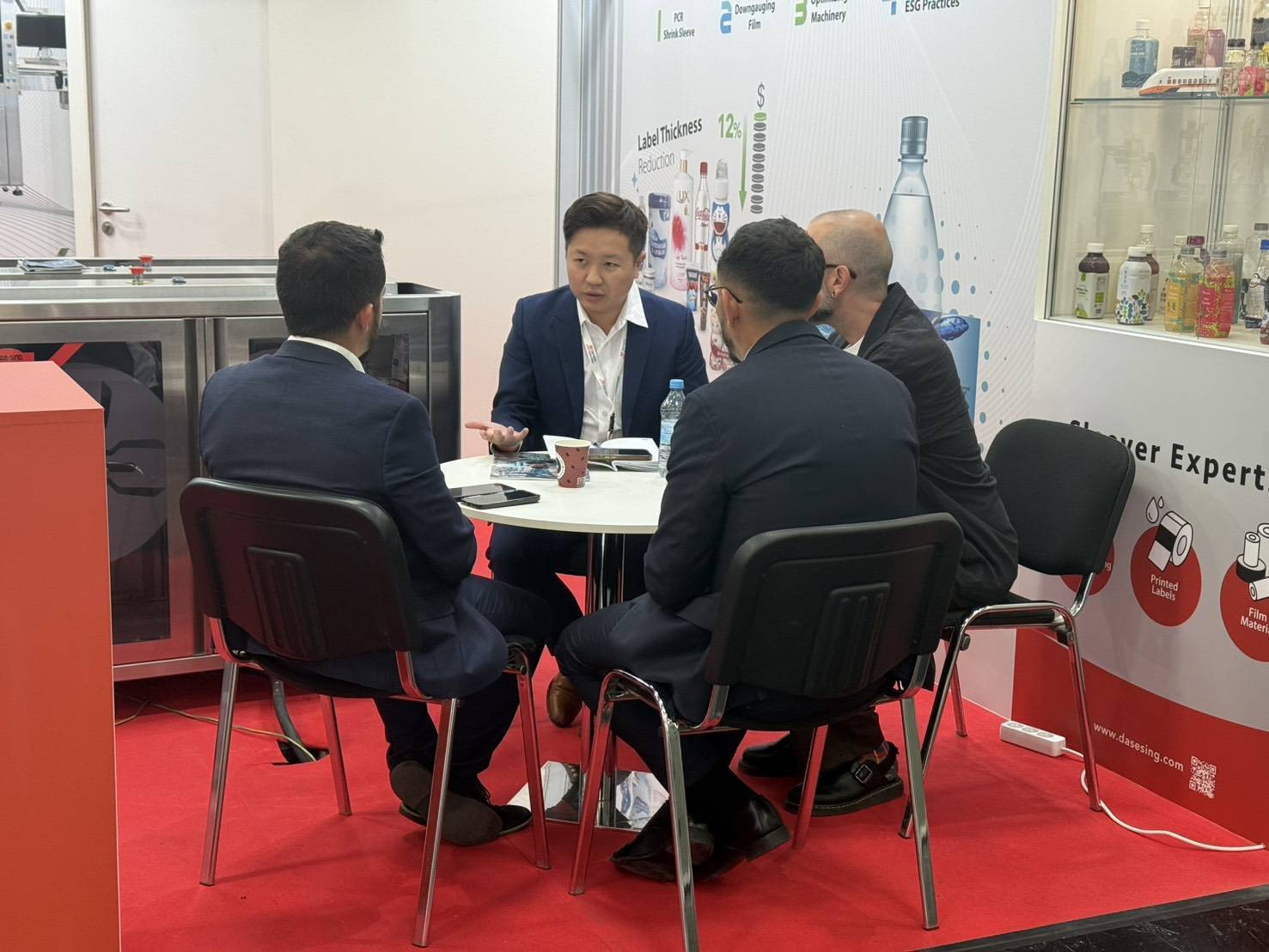

CEO Tony and Sales Representative Wanderson represented Dase-Sing at the show, engaging with international partners and showcasing the brand’s commitment to innovation and collaboration.

“We are confident that our technology can add meaningful value to your sleeve applicator requirements,” said Tony. “Dase-Sing remains committed to being a reliable partner for long-term success.”

With strong momentum from Drinktec Germany, Dase-Sing looks forward to continuing its global journey—next stop: Drinktec India 2025.

Explore how Dase-Sing’s downgauging sleeve, 1000BPM sleeve applicator, and sleeve material + printing + applicator total solution can elevate your production. Contact our team today to start your transformation.

Follow us in Linkedin

More video:20251107

https://www.dasesing.com/en/news-category/K04/1/Video

Contact us:

matt@dasesing.com