Shrink sleeve applicator machines are widely used in the dairy industry for their ability to apply visually appealing, protection, durable, and tamper-evident labels to a wide range of dairy products. These machines are designed to handle the diverse shapes and sizes of dairy packaging, from milk bottles and yogurt cups to ice cream tubs and aseptic containers.

Here's a breakdown of key aspects related to shrink sleeve machines for the dairy industry:

1. 360° Branding and Shelf Appeal: Shrink sleeves cover the entire surface of a container, offering maximum "real estate" for vibrant graphics, product information, and branding. This allows dairy products to stand out on crowded shelves.

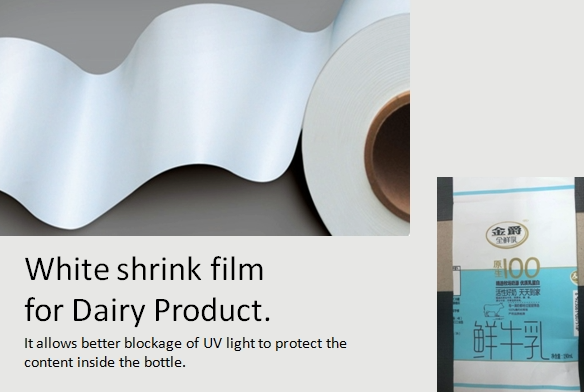

2. Protection and Durability: The reverse printing process used for shrink sleeves protects the graphics from scuffing, marring, and tearing, ensuring the product looks good throughout its shelf life. They also offer UV protection for light-sensitive dairy products, preserving taste, color, and vitamin levels.

3. Tamper Evidence: By extending the sleeve over the cap with a perforation, shrink sleeves provide a clear tamper-evident seal, reassuring consumers about product safety and integrity. This is particularly crucial for sensitive products like infant formula.

4. Versatility: Shrink sleeve machines can handle a wide variety of container materials (plastic, glass, metal) and complex shapes, including those with curves and unique designs that are challenging for traditional labels.

5. Sustainability Trends: The dairy industry is increasingly focused on sustainability. Manufacturers are developing eco-friendly shrink sleeve materials, such as those compatible with PET and HDPE recycling, and PCR films. Some solutions allow the sleeve to be recycled with the bottle, or feature perforations for easy consumer removal before recycling.

6. Hygiene and Washdown: Machines designed for the dairy industry are often built with stainless steel and low-voltage, IP65/66-rated electrics to withstand wet environments and frequent washdowns, meeting stringent hygiene regulations.

A shrink sleeve machine is a piece of equipment that applies shrink sleeve labels to product containers. These labels are typically made from heat-shrinkable plastic, which, when heated, conforms tightly to the unique shape of the container.

Shrink sleeve machines can be categorized into a few main types:

Automatic Shrink Sleeve Machines: These are the most common and efficient type. They can automatically perform all steps, including sleeve application, cutting, and heat shrinking. They are ideal for large-scale production lines.

Semi-Automatic Shrink Sleeve Machines: These machines require a human operator to manually place the sleeve onto the product container before the machine completes the subsequent heat-shrinking process. They are typically used for smaller production runs or situations that require greater flexibility.

Manual Shrink Sleeve Machines: These machines require manual handling for both the sleeve application and heat shrinking. They are the least efficient but also the lowest in cost, making them suitable for lab settings or very small-scale production.

| Type | Pros | Cons | Ideal For |

| Automatic Shrink Sleeve Machines | High efficiency, stable performance, suitable for high-speed production lines | High cost, large footprint, less suitable for small batches | Large food and beverage factories, cosmetic and pharmaceutical companies |

| Semi-Automatic Shrink Sleeve Machines | Lower cost, high flexibility, smaller footprint | Lower efficiency than fully automatic machines, requires manual operation | Small to medium-sized businesses, companies with diverse product lines |

| Manual Shrink Sleeve Machines | Lowest cost, simple structure, easy to operate | Low efficiency, limited output, suitable for lab or sample production | New product development, small workshops, handcrafted goods |

When selecting the right machine, you should consider several factors:

Production Volume: If you have a high production volume, an automatic shrink sleeve machine is recommended for efficiency and stability.

Budget: For a limited budget, semi-automatic or manual machines are more economical choices.

Product Containers: Consider the shape, size, and material of your containers to ensure they are compatible with the machine.

Future Expansion: Think about whether your production line will need to expand in the future and choose a machine that offers scalability.

By evaluating your production needs and budget, you can make an informed decision to select the best shrink sleeve machine for your business.

Dase-Sing Sleeve Applicators & Labels: The Complete Dairy Solution

Follow us in Linkedin

More video:20250813

https://www.dasesing.com/en/news-category/K04/1/Video

Contact us:

matt@dasesing.com