收縮套標是產品包裝領域的革命性產品,它提供無縫貼合的外形,提升貨架吸引力,並為品牌和產品資訊提供充足的展示空間。然而,在高速生產下始終保持這種完美外觀是一項挑戰。這時,一套強大的收縮套標偵測和剔除系統就顯得至關重要。如果沒有這套系統,大量缺陷產品會嚴重擾亂生產,並導致大量的生產恢復時間。

諸如白標(沒有套標)、標籤過高、標籤錯位或標籤連接膠帶偵測問題等意外缺陷可能會突然發生,並導致嚴重的套標錯誤。在生產過程中,及早檢測並剔除這些有缺陷的容器至關重要。

當套標機發生重大套標異常事件時,收縮套標系統應立即發出警報,提示操作員停止生產。這項主動措施可防止寶貴生產資源進一步浪費。

Dase-Sing 高標偵測與剔除測試

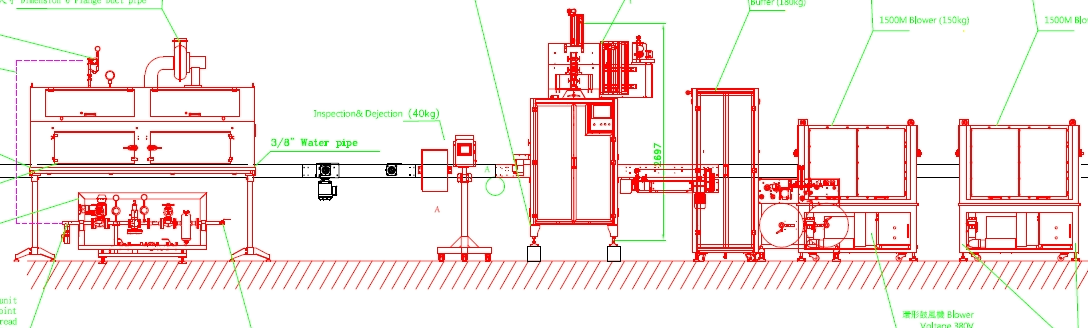

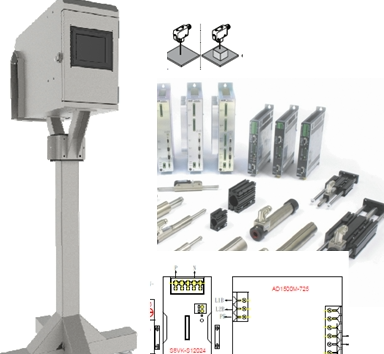

Dase-Sing 收縮套標系統有兩種偵測和剔除系統,每種系統各有優點。一種是與收縮套標機整合的檢測和剔除系統。另一種是獨立式系統,配備 OPCUA 通訊功能。如果客戶需要報告缺陷數量並傳送到 MES,Dase-Sing 的裝置可以透過 OPCUA 上傳資料。

在 DaseSing,我們深知高品質包裝在品牌認知中扮演至關重要的角色。錯位、撕裂或無套標的收縮套標會嚴重損害產品的整體形象。因此,我們倡導整合專為收縮套標應用量身定制的先進檢測和剔除技術。

為什麼要投資自動化套標品質檢測系統?

先進自動化套標品質檢測系統通常涉及什麼?

在 DaseSing,我們致力於提供確保最高品質包裝的解決方案。我們專注於收縮套標偵測和剔除系統,幫助企業交付外觀完美無瑕的產品,保護品牌形象,並優化生產流程。

More video:20250703

https://www.youtube.com/@dase-singpackagingtechnolo8451

Contact us:

matt@dasesing.com