Navigating the Trend of Downgauging in Shrink Sleeve Labels:Opportunities and Challenges

In the ever-evolving packaging industry, the trend toward downgauging shrink sleeve labels has gained significant traction. Downgauging refers to the process of reducing material thickness in shrink films, offering benefits like improved sustainability and reduced production costs. However, along with its advantages, this trend presents challenges that require careful navigation.

The Drive Behind Downgauging

The packaging industry's push for sustainability has accelerated the adoption of downgauged materials. Thinner films mean less plastic consumption, lower transportation costs due to reduced weight, and a smaller carbon footprint overall. Many brands are embracing these changes to align with eco-friendly goals, which are increasingly important to consumers.

Technological Challenges and Innovations

Cooperation between downgauging shrink sleeve labels and shrink sleeve applicator machines is critical for successful implementation.

Here's why:

1. Material Compatibility: Downgauged films are thinner and more delicate, so shrink sleeve applicator machines must be precisely calibrated to handle these materials without causing damage during application. This includes managing heat levels, film tension, and sleeve placement.

2. Enhanced Machinery Technology: Shrink sleeve applicator machines need advanced technology to accommodate downgauged films while maintaining high-speed operations. Features such as optimized seaming mechanisms, better film tracking, and high precision in cutting and shrinking are essential.

3. Consistency and Quality Control: Thinner films are more prone to issues like distortion, tearing, or uneven shrinking. Effective coordination between film properties and machine capabilities ensures consistent application quality, maintaining the visual appeal and durability of the final product.

4. Adaptability for Sustainability: Many downgauged films are designed with recyclability in mind. Shrink sleeve machines need to adapt to these new materials to ensure smooth processing while supporting sustainability goals.

5. Cost Efficiency: Well-synchronized cooperation reduces material waste and minimizes downtime, making the production process more cost-efficient and environmentally friendly.

In summary, the synergy between downgauged shrink sleeve labels and advanced shrink sleeve machines not only addresses technical challenges but also plays a pivotal role in achieving sustainability and operational efficiency.

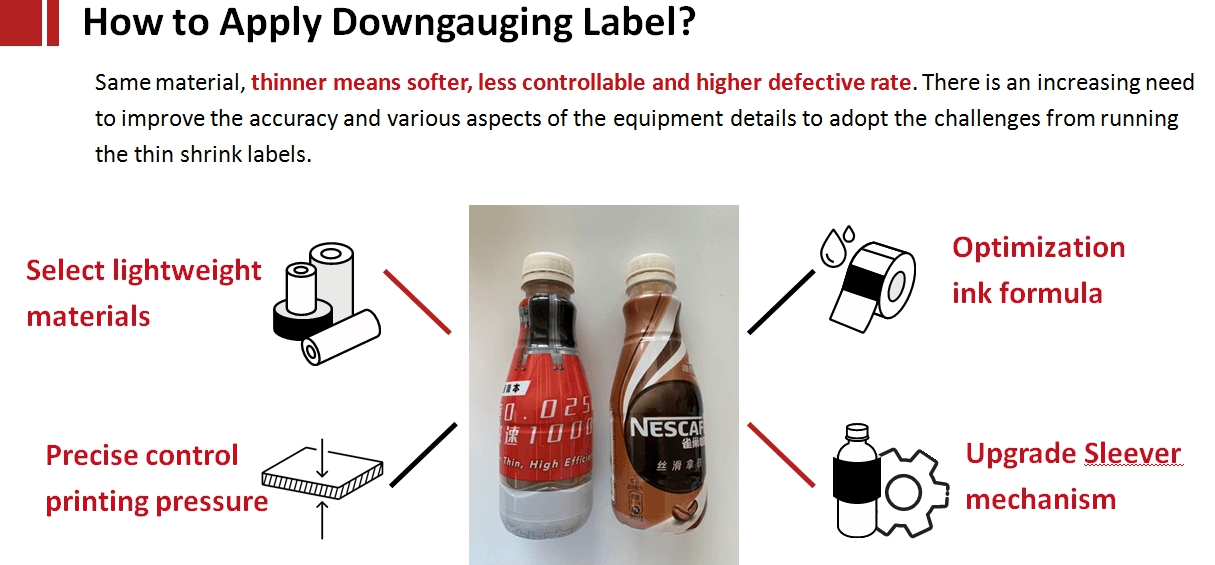

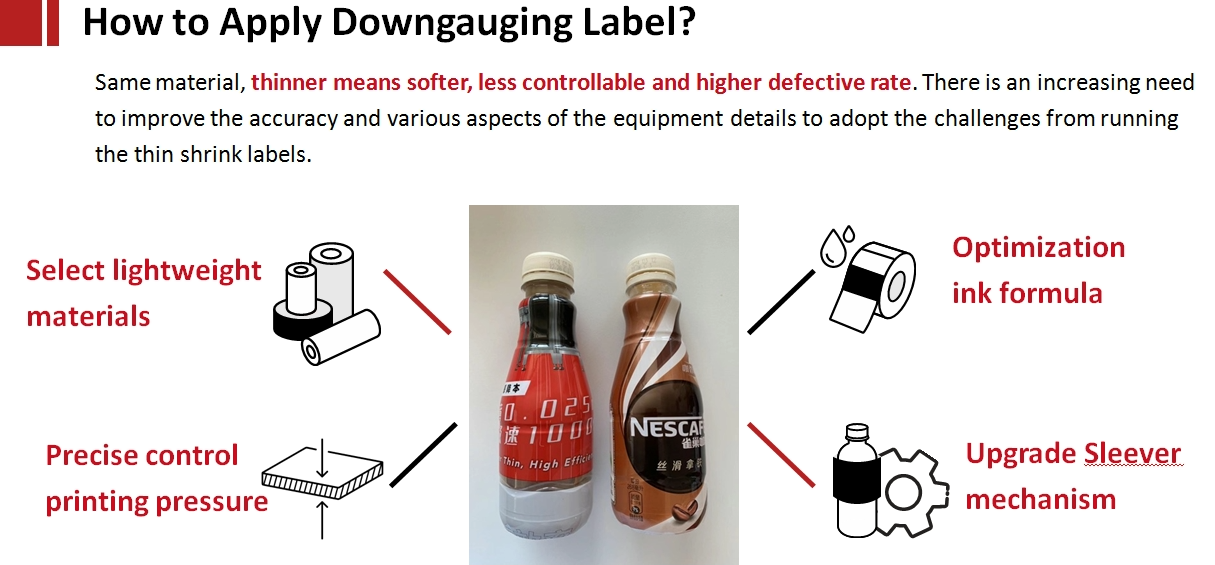

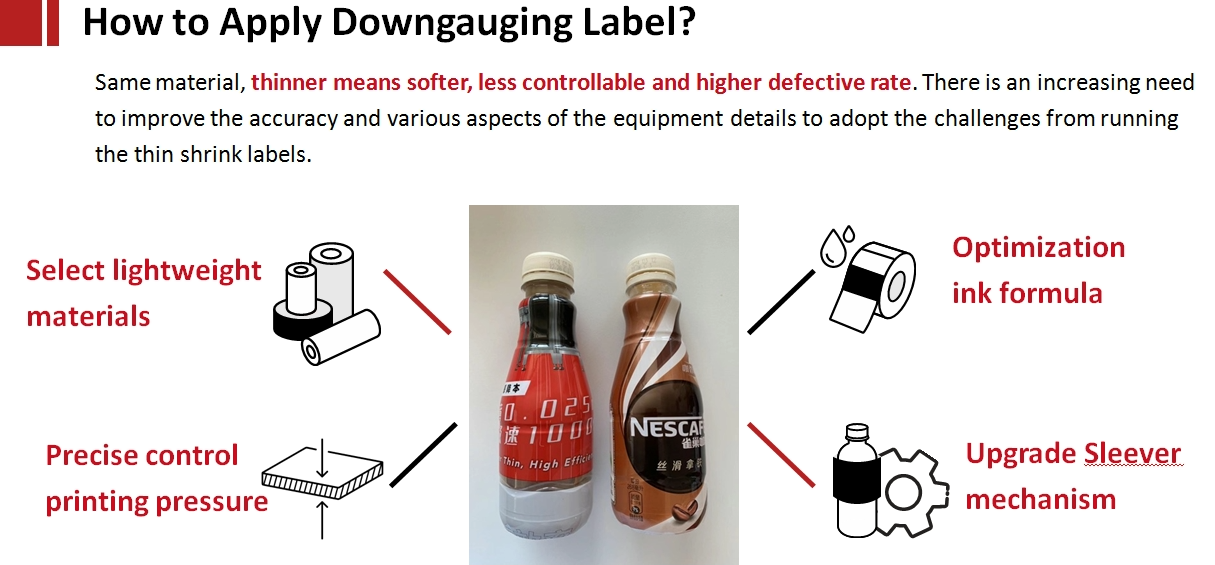

Downgauging Shrink Sleeve Label Challenge in Printing

Downgauging shrink sleeve labels presents several challenges in printing, particularly in maintaining quality and consistency. Here are some key difficulties:

-

Ink Adhesion Issues – Thinner films may have different surface properties, affecting how well ink adheres during printing. Specialized ink formulations and surface treatments are often required to ensure durability.

-

Distortion and Shrinkage – During the shrinking process, printed graphics can become distorted if not properly accounted for in the design phase. Advanced pre-press techniques help mitigate this issue.

-

Machine Compatibility – Printing machines must be calibrated to handle downgauged films without causing misalignment or damage. Adjustments in tension control and drying processes are crucial.

-

Sustainability Considerations – Many downgauged films are designed for recyclability, requiring printers to use eco-friendly inks and coatings that align with sustainability goals.

Final Thoughts

Downgauging shrink sleeve labels represents a step forward in sustainable packaging, offering opportunities for innovation while presenting technical challenges. As the industry continues to adapt and evolve, collaboration among manufacturers, designers, and recyclers will be key to unlocking its full potential.

Whether you're a packaging professional or a curious observer, these changes underscore the dynamic nature of the industry as it balances performance, cost, and environmental impact.

Dase-Sing indeed stands out as a comprehensive provider in the packaging industry. We offer a full selection of label materials, including shrink sleeve labels, and provide printing solutions tailored to various needs. Our expertise extends to manufacturing shrink sleeve applicator machines that cater to a wide range of speeds, from low to high, ensuring flexibility for different production requirements.

Additionally, Dase-Sing's machines come with a variety of feature options, such as advanced shrink tunnels, automated feeding systems, and precision controls..., which enhance efficiency and adaptability.

Dase-Sing's one-stop solution is an impressive approach to streamline the packaging process. By offering labels, printing solutions, and shrink sleeve applicator machines under one roof, we effectively eliminate the complexities and potential challenges involved in applying downgauged labels.

More video:20250416

https://www.dasesing.com/en/news-category/K04/1/Video

Contact us:

matt@dasesing.com